Disruptive Technologies in the Manufacturing Industry

With manufacturers trying to keep pace with consumer demand for high-quality products, companies must adopt data-driven technologies. This includes leveraging artificial intelligence (AI), augmented and virtual reality (AR and VR), 3D printing, and industrial internet of things (IIoT).

The areas of progress in conjunction with foundations of these technologies will improve production process through tracking and automation, while focusing on increasing throughput as well as output. Keep in mind, their use only scales when a strong technology foundation is laid — otherwise, new technology investments will be limited to specific initiatives.

Only 7% of Companies Are Delivering on Their Transformational Initiatives

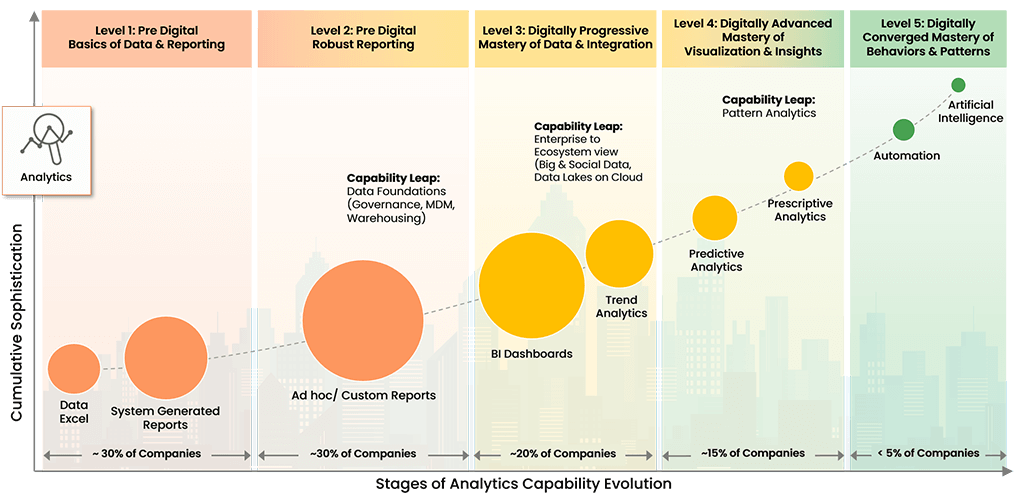

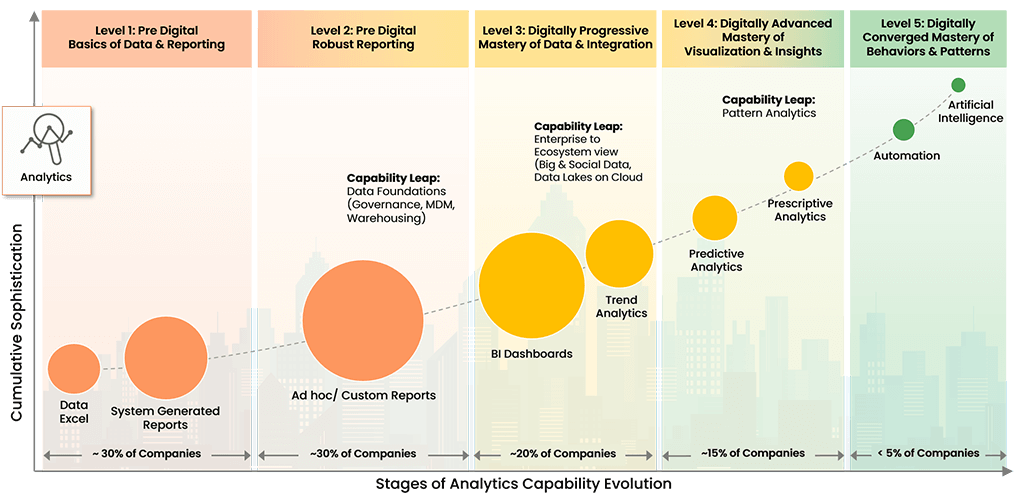

Our research has shown that 30% of companies will fail to survive this decade due to an inability to evolve digitally. To address this negative trend, we have developed the Digital Enterprise Evolution Model™ (DEEM).

Digital Enterprise Evolution Model™

Copyright © 2022 Trianz

DEEM allows our clients to recognize digital evolution patterns, implement benchmarking and prioritization strategies, and initiate application management protocols to satisfy stakeholder and market requirements.

El Internet industrial de las cosas (IIOT) aún no es una prioridad para la industria manufacturera. Solo el 8 % de las organizaciones de la industria manufacturera no consideran que la nube sea una prioridad para las aplicaciones del IIOT, y solo el 19 % de las organizaciones se encuentran en la etapa de justificación o análisis comercial.

Con una mayor demanda de personalización, mayores expectativas de los clientes y la creciente complejidad de la cadena de suministro internacional, los fabricantes necesitan analizar seriamente el IIoT para encontrar formas más innovadoras de seguir siendo competitivos.

El IIoT puede ayudar a los fabricantes a maximizar el valor de su negocio mediante la reducción de costos, un menor tiempo de comercialización, tiempos de producción en marcha, mayor seguridad y una mayor personalización de las operaciones de fabricación. Al aprovechar los datos del IIoT, los fabricantes pueden mejorar la previsión de la demanda, comprender mejor los procesos de la cadena de suministro y mejorar la experiencia general del cliente.

Gestión del capital humano (HCM) en empresas manufactureras

Los líderes de la industria manufacturera planean realizar importantes inversiones futuras en análisis avanzados para la gestión de servicios de compras y capital humano. Si bien la mayoría de las transformaciones digitales en estos dos grupos son reacciones a acciones competitivas o impulsadas por los clientes, el análisis predictivo determinará cómo, cuándo y en qué medida se realizará la transformación en el futuro.

Al adoptar plataformas de gestión de capital humano basadas en la nube para brindar análisis, los fabricantes no solo podrán mejorar la experiencia de los empleados, sino también aprovechar las métricas operativas para ayudar a las partes interesadas a comprender mejor las contribuciones de los empleados.

Esto ayudará a los fabricantes a darse cuenta de la urgencia de mejorar las habilidades de sus empleados y de abordar la brecha de habilidades de estos. Además, los líderes reconocerán la necesidad de transformar las funciones de aprendizaje de los empleados y crear nuevas capacidades para atraer, incorporar y retener a los empleados.

Experimente la diferencia de Trianz

Trianz permite la transformación digital a través de estrategias efectivas y excelencia en la ejecución. En colaboración con líderes empresariales y tecnológicos, ayudamos a formular y ejecutar estrategias operativas para lograr los resultados comerciales previstos mediante la incorporación de lo mejor en consultoría, experiencias tecnológicas y modelos de ejecución.

Con el respaldo de nuestros conocimientos, investigaciones y perspectivas, ayudamos a nuestros clientes a transformar sus ecosistemas empresariales y lograr un rendimiento superior aprovechando los paradigmas de infraestructura, nube, análisis, seguridad y tecnología digital. Comuníquese con nosotros para ponerse en contacto o para obtener más información.